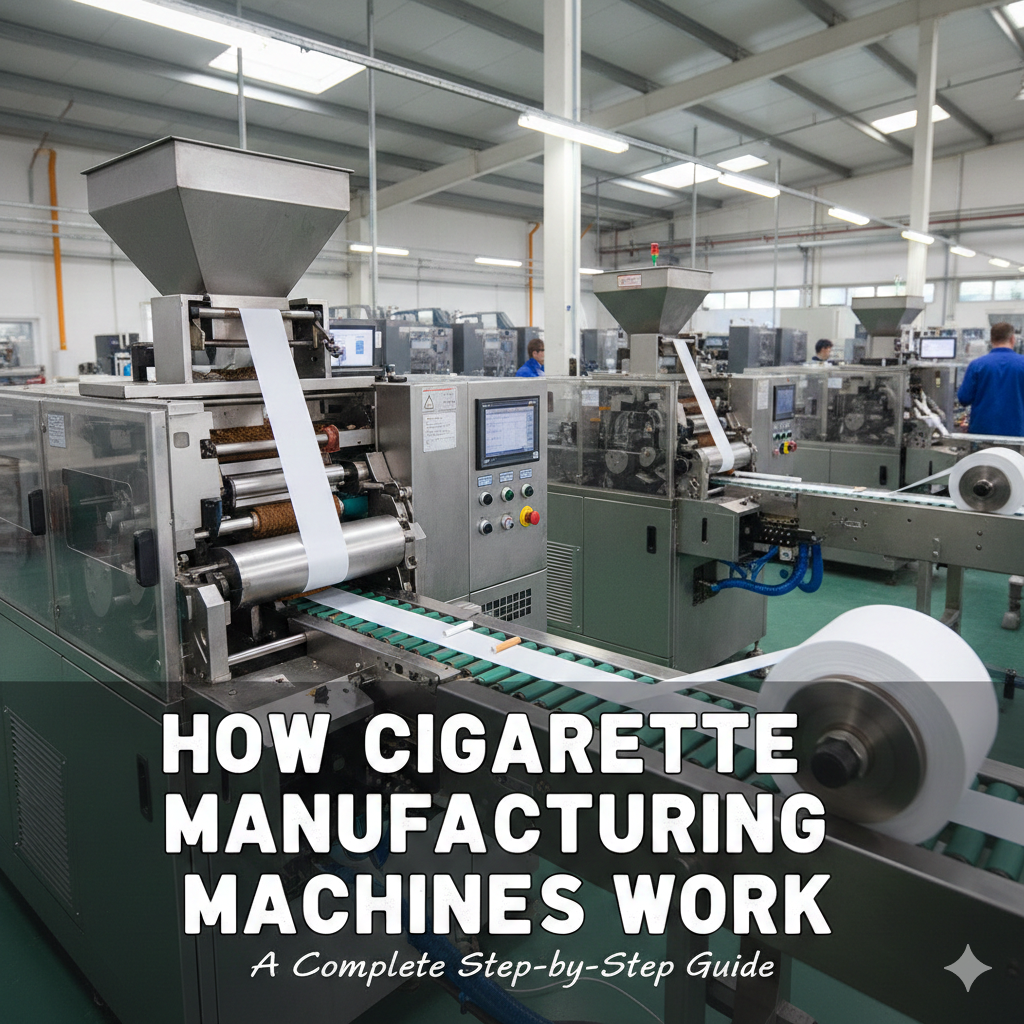

Top 5 Reasons to Upgrade Your Tobacco Machines

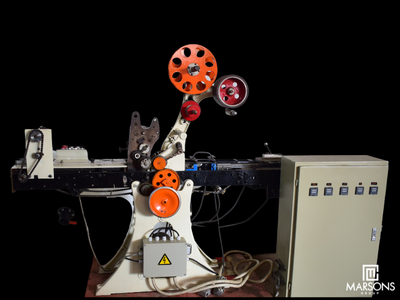

The tobacco manufacturing industry is evolving rapidly with increasing demand for higher production speeds, consistent quality, and cost efficiency. Outdated machinery can limit growth, increase operational costs, and reduce competitiveness. Upgrading to advanced equipment from experienced manufacturers like Marsons Group can significantly improve overall factory performance. Below are the top five reasons why upgrading your tobacco machines is a smart