Cigarette packaging plays a vital role in product protection, branding, compliance, and customer experience. Among the most significant advancements in the tobacco industry has been the evolution of cigarette box wrapping machines—shifting from traditional manual methods to highly efficient and automated systems. This transformation not only improved packaging speed and consistency but also reshaped the way tobacco companies approach manufacturing logistics.

In this article, we explore the historical journey of cigarette box wrapping, the technology behind modern machines, and what the future holds for this crucial aspect of cigarette production.

1. Introduction to Cigarette Box Wrapping

Cigarette box wrapping involves enclosing cigarette cartons or boxes in protective film or paper to maintain freshness, ensure hygiene, prevent tampering, and meet branding requirements. As competition intensifies and compliance regulations evolve, tobacco companies are investing in better wrapping technology to remain competitive and meet quality expectations.

From single-layer cellophane wrapping to multi-layer tamper-proof films, the process has come a long way—thanks largely to automation.

2. Early Days: Manual Wrapping Techniques

The Humble Beginnings

In the early 20th century, cigarette boxes were wrapped by hand using thin paper or cellophane. Skilled workers would fold and seal each box individually, a slow and labor-intensive process. While effective for small-scale production, this method was highly inconsistent and prone to errors.

Limitations of Manual Wrapping

-

Low throughput: Wrapping a few hundred boxes per day was the maximum capacity.

-

Inconsistency: Variability in packaging tightness, alignment, and sealing.

-

Higher labor costs: Required more human intervention and training.

-

Poor tamper resistance: Manually wrapped boxes were easier to tamper with or damage.

3. The Rise of Semi-Automatic Wrapping Machines

Bridging the Gap

By the mid-20th century, semi-automatic wrapping machines emerged as a solution to meet growing demand. These machines required human assistance to load boxes and initiate wrapping, but the sealing and folding mechanisms were motor-driven.

Advantages Over Manual Methods

-

Faster production compared to manual wrapping

-

Better consistency in sealing and appearance

-

Reduced operator fatigue

-

Suitable for medium-scale tobacco manufacturers

However, semi-automatic systems still needed supervision, and frequent maintenance was a common challenge.

4. Full Automation and Industry 4.0

The Shift to Fully Automated Wrapping Machines

The need for higher output, efficiency, and consistency led to the development of fully automatic cigarette box wrapping machines. These advanced systems handle every step—from box feeding to film application, sealing, and ejection—without human involvement.

Automation became even more powerful with the integration of Industry 4.0 technologies, such as:

-

IoT sensors for machine health monitoring

-

AI-based diagnostics for predictive maintenance

-

SCADA systems for real-time monitoring

-

Remote control and diagnostics via cloud-based platforms

Impact on the Tobacco Industry

-

Speeds of up to 60–100 boxes per minute

-

Drastic reduction in packaging errors

-

Enhanced compliance with international standards

-

Better tracking and traceability for quality control

5. Key Features of Modern Cigarette Box Wrapping Machines

Today’s machines are compact, fast, and intelligent. Some of the core features include:

-

PLC and HMI Control Panels: Easy to operate, program, and monitor.

-

Adjustable Wrapping Speed: Accommodates different production line capacities.

-

Servo-driven Film Feeders: For precise film cutting and application.

-

Automatic Box Size Detection: Allows for flexible production.

-

Multiple Film Compatibility: Works with BOPP, PVC, and recyclable materials.

-

Edge Sealing and Heat Shrinking: Ensures tight, professional finish.

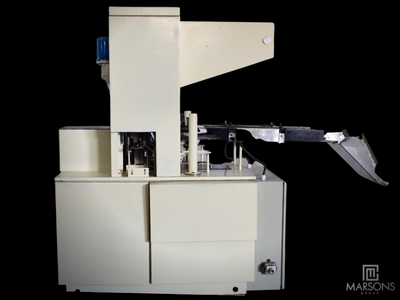

Leading manufacturers such as Marson Group offer high-speed wrapping machines specifically tailored for cigarette box packaging.

6. Benefits of Automated Wrapping for Manufacturers

1. Increased Production Speed

High-speed machines can process thousands of units per hour, drastically improving output and reducing lead times.

2. Enhanced Product Consistency

Uniform wrapping maintains brand aesthetics and consumer trust.

3. Reduced Labor Costs

With minimal human involvement, labor dependency drops, lowering operational costs.

4. Improved Quality Control

Automated sensors and software catch defects or inconsistencies in real-time.

5. Better Integration

Can be seamlessly integrated with cartoning, labeling, and track-and-trace systems.

7. Regulatory Compliance and Packaging Standards

Global Packaging Norms

Governments enforce strict packaging guidelines for cigarettes to discourage smoking and ensure consumer safety. Automated wrapping machines are instrumental in meeting these standards:

-

Tamper-proof Seals

-

Printed Health Warnings

-

Excise Tax Stamps

-

Barcode and QR Code Integration

8. Sustainability and Eco-Friendly Wrapping Trends

Green Packaging in Tobacco

With growing environmental awareness, cigarette manufacturers are switching to biodegradable films, recyclable paper, and reduced plastic usage.

Automated machines now support:

-

Use of bio-cellulose films

-

Recyclable polypropylene (PP) wrapping

-

Minimal waste generation through precision film cutting

Some brands are also moving toward zero-plastic initiatives, using paperboard cartons and paper wraps instead of cellophane.

9. Challenges in Transitioning from Manual to Automatic

Capital Investment

The biggest barrier for smaller manufacturers is the high initial cost of automated wrapping machines. While ROI is substantial over time, the upfront cost can be daunting.

Training & Change Management

Automation requires a skilled workforce to operate and maintain machines, necessitating training programs and process restructuring.

Machine Downtime and Maintenance

Even the most advanced machines require periodic servicing. A breakdown in an automated line can halt entire production runs, making preventive maintenance critical.

Final Thoughts

The evolution from manual wrapping to automated cigarette box wrapping machines marks a major leap forward for the tobacco industry. Automation has not only enhanced efficiency and product quality but has also become essential for regulatory compliance and sustainable practices.

For manufacturers aiming to stay ahead in a highly competitive and regulated market, investing in modern cigarette box wrapping machines is no longer optional—it’s strategic.