Cigarette rolling machines have revolutionized how tobacco products are manufactured, offering efficiency, speed, and precision that manual processes simply cannot match. Whether you operate a large-scale cigarette production facility or manage a smaller setup, maintaining your cigarette tobacco rolling machine is crucial to ensuring long-lasting performance, minimizing downtime, and achieving consistently high-quality output.

Just like any sophisticated industrial equipment, these machines require regular maintenance, inspection, and cleaning to keep them performing at their best. Neglecting proper care not only shortens the lifespan of the equipment but can also lead to costly breakdowns, poor cigarette quality, and production delays.

In this comprehensive guide, we’ll explore essential cigarette tobacco rolling machine maintenance tips, helping you maximize productivity, minimize wear and tear, and ensure your equipment operates efficiently for years to come.

Introduction: Why Maintenance Matters

Your cigarette tobacco rolling machine is the heart of your production line. It’s responsible for rolling, filling, and shaping thousands (or even millions) of cigarettes daily. Over time, the machine endures friction, heat, and stress from constant operation, which can lead to component wear and mechanical failure.

Regular maintenance:

- Prevents unexpected breakdowns

- Maintains product quality

- Reduces repair costs

- Improves machine efficiency and lifespan

When a machine runs smoothly, it not only saves you money but also ensures every cigarette meets your quality standards — uniform size, proper density, and a perfect roll.

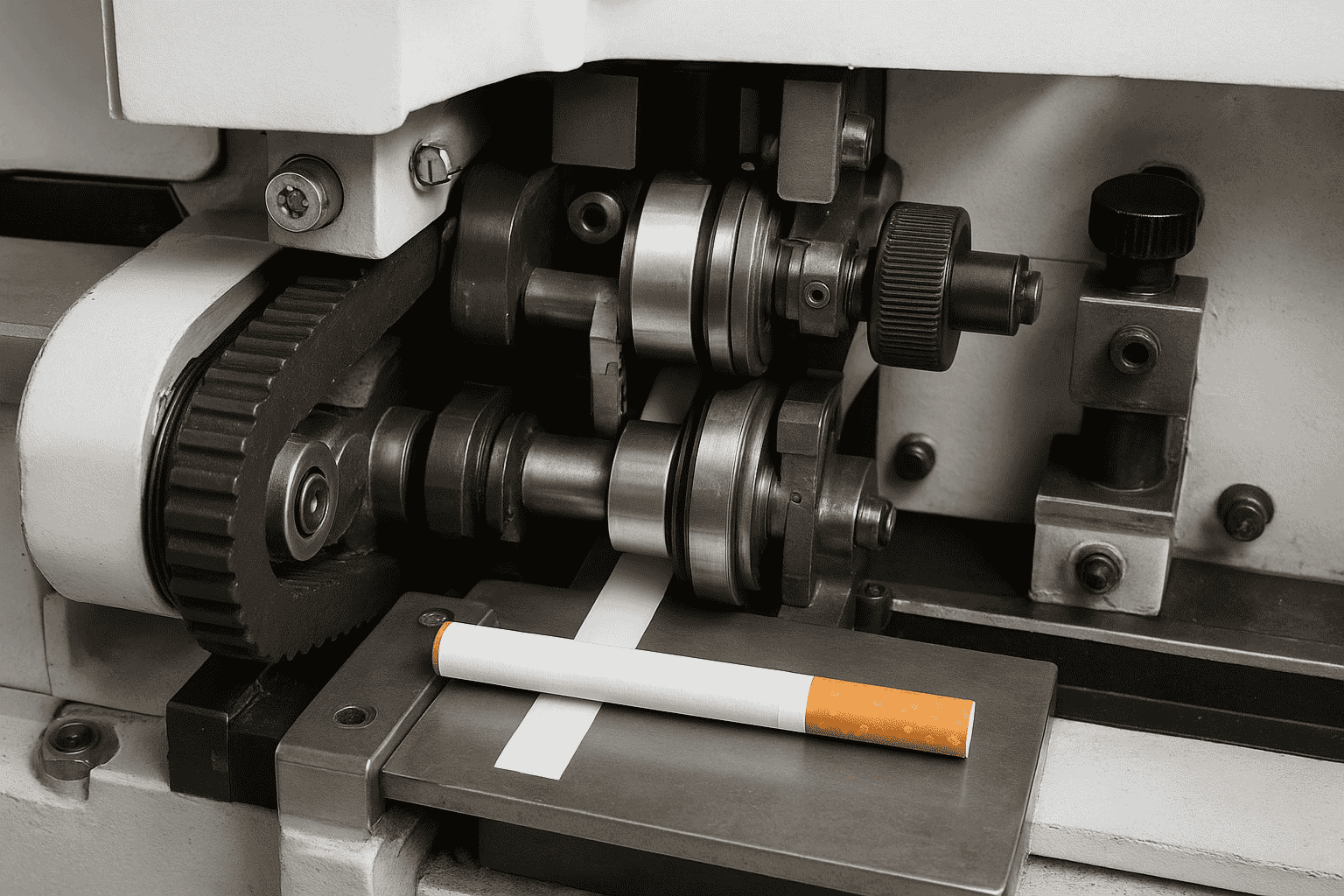

Understanding How a Cigarette Rolling Machine Works

Before diving into maintenance, it’s important to understand how the machine operates.

A cigarette rolling machine typically consists of:

- Feeding system: Feeds shredded tobacco evenly.

- Rolling belt and garniture: Rolls and compacts tobacco with the paper.

- Paper feed system: Supplies the wrapping paper.

- Cutting and filter attachment section: Cuts rolled cigarettes to length and attaches filters.

- Control panel: Manages temperature, speed, and rolling parameters.

Each part plays a vital role, and a failure in even one system — like a misaligned roller or clogged tobacco feed — can disrupt the entire operation.

Common Problems Caused by Poor Maintenance

Without regular care, cigarette rolling machines can experience several issues that affect both production and product quality.

Common problems include:

- Irregular cigarette length or shape

- Inconsistent tobacco filling

- Paper tearing during rolling

- Belt slippage or tension issues

- Jamming of tobacco feed

- Electrical faults or overheating

- Increased machine vibration or noise

Most of these problems stem from lack of cleaning, lubrication, or worn-out components. Routine maintenance eliminates these risks and ensures long-term reliability.

Daily Maintenance Checklist

Daily care is the foundation of proper maintenance. At the end of each shift or production cycle, operators should perform these essential checks:

- Clean tobacco dust and residue from rollers, belts, and feeding areas using a soft brush or air compressor.

- Inspect belts and rollers for debris or build-up that could affect rolling performance.

- Check tobacco feed flow — ensure no blockages or uneven distribution.

- Wipe down sensors and control panels with a dry, lint-free cloth to prevent malfunction.

- Empty waste collection trays and ensure paper scraps are removed.

- Check for unusual sounds or vibrations during operation — these can indicate early signs of wear.

Performing these simple tasks daily reduces downtime and improves overall machine performance.

Weekly and Monthly Maintenance Tasks

Beyond daily checks, weekly and monthly maintenance routines are crucial for more thorough inspection and servicing.

Weekly Maintenance:

- Inspect belts and garniture tapes for tension and signs of wear.

- Check alignment of rollers and cutting blades.

- Lubricate all moving parts (refer to manufacturer’s lubrication chart).

- Clean tobacco feeding channels more deeply with appropriate tools.

- Test machine calibration for cigarette length and weight consistency.

Monthly Maintenance:

- Inspect electrical wiring and connectors for loose or frayed ends.

- Check motor performance and bearings for unusual friction.

- Inspect filters, sensors, and suction systems.

- Examine heating elements (if any) for signs of buildup or corrosion.

By sticking to this routine, you can prevent unexpected machine breakdowns and maintain smooth production.

Lubrication: Keeping Your Machine Running Smoothly

Proper lubrication is one of the most important aspects of cigarette rolling machine maintenance. Every moving component — gears, shafts, bearings, and belts — relies on lubrication to minimize friction and wear.

Best Lubrication Practices:

- Use manufacturer-recommended lubricants only.

- Do not over-lubricate; excess oil attracts dust and tobacco particles.

- Apply oil to bearings, chains, and rollers at regular intervals.

- Wipe away old or contaminated lubricant before applying new oil.

- Keep a lubrication log to track when and where oil was applied.

Failure to lubricate can lead to overheating, increased energy consumption, and premature part failure.

Cleaning the Machine Properly

Cleaning is not just about appearance — it directly impacts the machine’s efficiency and performance.

Daily Cleaning:

- Remove tobacco particles from rollers, belts, and the garniture section.

- Use compressed air to clean hard-to-reach spots.

- Avoid water or corrosive cleaners that may damage components.

Deep Cleaning (Weekly or Monthly):

- Dismantle the tobacco feeding tray, hopper, and paper path for a complete clean.

- Soak removable parts (if allowed) in mild cleaning solution, then dry thoroughly.

- Clean sensors, filters, and nozzles to prevent buildup.

- Reassemble with care and perform a test run before restarting production.

Proper cleaning ensures smoother operation and prevents tobacco dust from clogging the machine or affecting product quality.

Checking and Replacing Worn-Out Parts

Every rolling machine has components that naturally wear out over time — belts, rollers, blades, bearings, and garniture tapes are common examples.

Signs of Wear:

- Uneven rolling or paper feed

- Visible cracks or thinning on belts

- Increased vibration or unusual noise

- Slippage in the tobacco rolling section

Regular inspection helps you identify and replace parts before they fail. Always keep spare parts on hand for essential components, and follow the manufacturer’s replacement intervals.

Electrical and Control System Maintenance

The electrical system is the brain of your cigarette rolling machine. Faulty wiring, sensors, or control units can lead to system errors or unsafe conditions.

Maintenance Tips:

- Inspect cables and connectors for wear or looseness.

- Clean sensors with a dry, anti-static cloth.

- Check voltage stability and grounding regularly.

- Backup control software or PLC settings periodically.

- Avoid moisture exposure near electrical panels.

If you notice irregular sensor readings or software glitches, consult a certified technician immediately to avoid larger issues.

Calibrating the Machine for Consistent Cigarette Quality

Calibration ensures that every cigarette is rolled with the same size, density, and paper length. Over time, mechanical vibration or component wear can cause the machine to lose calibration.

Calibration Steps:

- Test-roll a few cigarettes and measure length, diameter, and density.

- Adjust roller pressure, belt speed, and garniture alignment as needed.

- Verify paper cutting accuracy.

- Store calibration data for future reference.

Recalibrate the machine monthly or after part replacement to maintain quality consistency and reduce waste.

Temperature and Humidity Control in the Work Area

Environmental factors can also impact machine performance and tobacco quality.

Ideal Conditions:

- Temperature: 20–25°C (68–77°F)

- Humidity: 60–70%

If humidity is too low, tobacco becomes dry and brittle, causing uneven rolling and paper tears. Too high humidity, on the other hand, leads to clumping and feeding issues.

Maintain controlled conditions in your production area with humidifiers, dehumidifiers, and ventilation systems to protect both machine and tobacco.

Operator Training and Best Practices

Even the best-maintained machines can fail if operated incorrectly. Trained operators are essential to safe and efficient machine use.

Operator Training Should Include:

- Understanding machine controls and indicators.

- Recognizing early signs of malfunction.

- Performing routine cleaning and lubrication.

- Following emergency shutdown procedures.

- Adhering to manufacturer maintenance schedules.

Promoting awareness and accountability among operators greatly reduces the risk of accidental damage and downtime.

Preventive Maintenance Schedule

Preventive maintenance is more cost-effective than reactive repairs. A structured schedule ensures every component gets serviced on time.

| Frequency | Task | Purpose |

|---|---|---|

| Daily | Clean rollers, remove debris, inspect belts | Prevent dust buildup and wear |

| Weekly | Lubricate moving parts, check alignment | Maintain smooth operation |

| Monthly | Inspect electrical systems, calibrate machine | Ensure performance stability |

| Quarterly | Replace worn belts/blades, deep clean machine | Extend lifespan and reduce failures |

| Annually | Full inspection by manufacturer or technician | Overhaul and performance audit |

Following this plan can extend your machine’s life by several years and keep production running efficiently.

Signs Your Rolling Machine Needs Professional Servicing

Sometimes, maintenance alone isn’t enough. If you notice any of these signs, it’s time to call a professional technician:

- Repeated tobacco jams or feed failures

- Electrical faults or control errors

- Cigarette size inconsistency despite calibration

- Overheating or burning smell from the machine

- Persistent noise or vibration issues

Professional servicing ensures deep mechanical and software diagnostics that regular maintenance cannot address.

Conclusion: Extend the Life of Your Rolling Machine

Your cigarette tobacco rolling machine is a major investment — one that pays off only when properly cared for. Regular maintenance not only keeps production smooth but also ensures your cigarettes meet the highest standards of consistency, appearance, and quality.

To recap, here are the key maintenance takeaways:

- Perform daily cleaning and inspections to prevent buildup.

- Follow weekly lubrication and alignment checks.

- Replace worn parts before they cause failures.

- Maintain ideal environmental conditions for smooth operation.

- Train operators and stick to a preventive maintenance schedule.

By following these simple yet effective maintenance tips, you can maximize the lifespan of your cigarette rolling machine, minimize downtime, and ensure your production line remains efficient and profitable for years to come.